Hey there! As a supplier of manganese sulphate feed grade, I often get asked about the difference between feed - grade and industrial - grade manganese sulphate. So, I thought I'd write this blog to clear things up.

Let's start with the basics. Manganese sulphate is a chemical compound that contains manganese, an essential trace element for both animals and various industrial processes. But the requirements for these two different applications are quite different, which leads to the distinction between feed - grade and industrial - grade products.

Purity and Impurities

One of the most significant differences between feed - grade and industrial - grade manganese sulphate is the purity level. Feed - grade manganese sulphate needs to be of a much higher purity. This is because it's going to be used in animal feed, and any impurities could potentially harm the animals.

For animals, even small amounts of certain heavy metals or other contaminants can have negative health effects. So, when we produce Manganese Sulphate Feed Grade, we have strict quality control measures in place to ensure that the product is as pure as possible. We need to keep the levels of heavy metals like lead, arsenic, and cadmium extremely low.

On the other hand, industrial - grade manganese sulphate doesn't have to meet such high purity standards. In industrial applications, a certain level of impurities might be acceptable as long as they don't interfere with the specific process. For example, in the production of batteries or fertilizers, the presence of some impurities might not significantly affect the final product's performance.

Particle Size and Solubility

Particle size and solubility also play an important role in differentiating between the two grades. Feed - grade manganese sulphate usually has a specific particle size range. This is crucial because it affects how well the manganese sulphate can be mixed with other feed ingredients. If the particles are too large, they might not distribute evenly in the feed, which could lead to some animals getting more manganese than others.

Solubility is also a key factor. In animal feed, the manganese sulphate needs to be highly soluble so that it can be easily absorbed by the animals' digestive systems. When the manganese is readily available in the digestive tract, it can be efficiently utilized by the animals for various physiological functions, such as bone development, immune system support, and antioxidant defense.

Industrial - grade manganese sulphate, however, might have different requirements for particle size and solubility depending on the application. In some industrial processes, a slower dissolution rate might be preferred, or the particle size might need to be optimized for better handling or reaction kinetics.

Composition and Nutritional Value

As a feed - grade supplier, I focus not only on the chemical purity but also on the nutritional value of the product. Feed - grade manganese sulphate is formulated to provide the right amount of bioavailable manganese for animals. Manganese is an essential nutrient for animals, and it's involved in many important metabolic processes.

For example, in poultry, manganese is necessary for proper bone formation and eggshell quality. In swine, it plays a role in reproductive performance and immune function. So, when we produce feed - grade manganese sulphate, we ensure that it contains the right form and amount of manganese that animals can actually use.

Industrial - grade manganese sulphate, on the other hand, is mainly used for non - nutritional purposes. Its composition is tailored to meet the specific chemical and physical requirements of the industrial process it's used in. For instance, in the production of ceramics, the manganese sulphate might be used as a colorant, and its composition would be optimized for this particular function.

Regulatory Requirements

The regulatory environment for feed - grade and industrial - grade manganese sulphate is also quite different. Feed - grade products are subject to strict regulations by government agencies responsible for animal health and food safety. These regulations are in place to protect the health of animals and, ultimately, the safety of the food products derived from them.

For example, in many countries, there are maximum allowable limits for impurities in feed - grade manganese sulphate, as well as requirements for labeling and documentation. Feed manufacturers need to ensure that the products they use meet these regulatory standards to avoid any legal issues.

Industrial - grade manganese sulphate is also regulated, but the regulations are more focused on environmental and industrial safety aspects. For example, there might be regulations regarding the disposal of waste products generated during the production or use of industrial - grade manganese sulphate to prevent environmental pollution.

Applications

The applications of feed - grade and industrial - grade manganese sulphate are, of course, very different. As I mentioned earlier, feed - grade manganese sulphate is used primarily in animal feed. It's an important additive in the diets of various livestock, poultry, and aquaculture species.

By adding Manganese Sulphate Feed Grade to animal feed, we can help ensure that the animals get enough manganese to support their growth, development, and overall health. This, in turn, can lead to better productivity and quality of animal products, such as meat, milk, and eggs.

Industrial - grade manganese sulphate has a wide range of applications in different industries. It's used in the production of batteries, where it can improve the performance and stability of the battery. It's also used in the manufacturing of fertilizers, as manganese is an important micronutrient for plants. In addition, it can be used in the production of pigments, ceramics, and other industrial materials.

Pricing

The difference in quality, production processes, and regulatory requirements also affects the pricing of feed - grade and industrial - grade manganese sulphate. Feed - grade products are generally more expensive because of the higher purity requirements and the strict quality control measures involved in their production.

Producing feed - grade manganese sulphate requires more sophisticated purification processes and more frequent testing to ensure compliance with regulatory standards. All these additional steps add to the cost of production, which is then reflected in the price.

Industrial - grade manganese sulphate, on the other hand, can be produced more cost - effectively because it doesn't have to meet the same high - end quality standards. This makes it a more affordable option for industrial applications where cost is a major consideration.

Other Related Feed - Grade Products

If you're in the animal feed industry, you might also be interested in other feed - grade trace elements. For example, Ferrous Sulphate Feed Grade is another important additive. Iron is essential for animals as it's involved in oxygen transport and energy metabolism.

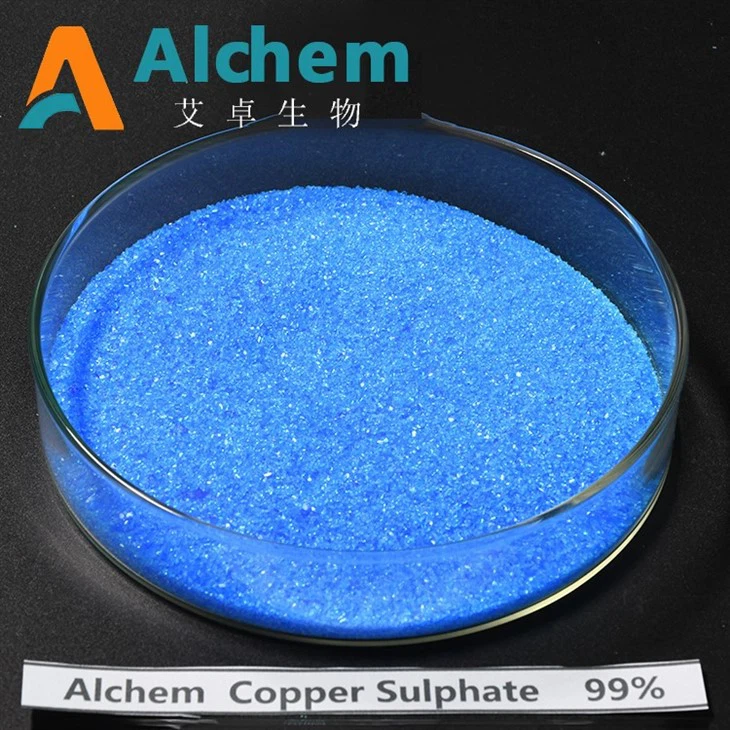

Copper Sulphate Feed Grade is also commonly used in animal feed. Copper plays a role in many physiological processes, including immune function, iron metabolism, and pigmentation.

Conclusion

In conclusion, the difference between feed - grade and industrial - grade manganese sulphate is quite significant. From purity and impurities to particle size, solubility, composition, regulatory requirements, applications, and pricing, each grade is tailored to meet the specific needs of its intended use.

As a supplier of Manganese Sulphate Feed Grade, I'm dedicated to providing high - quality products that meet the strict standards of the animal feed industry. If you're involved in animal feed production and are looking for a reliable source of manganese sulphate feed grade, I'd love to talk to you. Whether you have questions about our products, need technical support, or are interested in placing an order, don't hesitate to reach out. Let's work together to ensure the health and productivity of your animals.

References

- National Research Council. (2012). Nutrient Requirements of Swine. National Academies Press.

- National Research Council. (1994). Nutrient Requirements of Poultry. National Academies Press.

- Various regulatory documents from government agencies responsible for animal health and industrial safety.